MMS specialises in development of membrane processes for dairy, food & beverages, biotech, chemical and water applications. Our goal is to allow customers to establish the solution, feasibility, costs, speed of realisation, and consequences of a novel process.

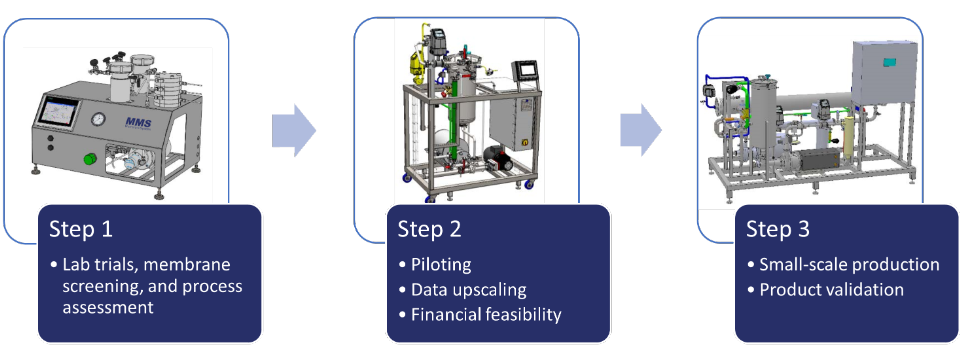

We offer a 3-step development process to evaluate a new concept. In step 1, we test different solutions and screen different membrane types on lab- scale on a sample from the customer. Test results are documented in a comprehensive report.

If the report is promising, the 2nd step is to scale up the screening results to pilot testing of the process in Zurich or on the customer’s site. The purpose is to validate the process, scale up data, and assess financial feasibility.

After a successful piloting period, step 3 is small-scale production and product validation to obtain all necessary data and information to give the customer a solid rationale before deciding on investment in an industrial-scale system.

We offer a wide range of lab units and pilot systems for rental or purchase, which can be equipped with different membrane types:

Download brochure MMS Process Development Service.

See also Lab Units, Pilots, and Industrial Membrane Systems for any need.

Contact us for more information on what MMS can offer.